Amorphous Silicon by LPCVD

Polysilicon films are grown at 600-650 °C and amorphous silicon films (a-Si) are grown at 500-550 °C. Lower temperatures result in lower stress and smaller grain size. A post-growth anneal can be used to relieve film stress. Both large-grained and amorphous films have compressive stresses while smaller grains have tensile stresses. By alternating compressive and tensile layers, the overall stress can be kept low enough that a stress-relieving anneal is not required. Smaller grains have lower thermal conductivities and are etched faster by HF. Between 600 and 650 °C the film's orientation is predominantly (110), while at higher temperatures (100) dominates.

- Typical Film Thickness: 0.1 to 2 µm

- Batch Size: 50

- Deposition rate: 1-3 nm/min. (10 - 30 Å/min.)

- Deposition Temperature: 500 - 550 °C

- Refractive index at 550nm

- Uniformity: < 3% using 1 σ

- Gases: Silane SiH4

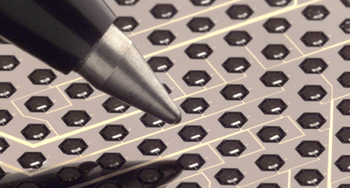

Applications: thin-film transistors for LCDs, thin-film photovoltaic solar cells

LPCVD Processes

- Silicon Carbide Devices

- Silicon Nitride Resonators

- Doped Silicon by LPCVD

- POLYSILICON LPCVD WITH SILANE (SiH4)

- POLYSILICON LPCVD WITH DISILANE (Si2H6)

- LTO, DOPED LTO, BPSG, BSG, AND PSG LPCVD

- HTO LPCVD

- TEOS LPCVD

- Silicon Nitride LPCVD

- Low-Stress Silicon Nitride LPCVD

- Stochiometric Silicon Nitride LPCVD

- Silicon Oxynitride (SiNxOy) LPCVD

- Silicon Germanium (Si-Ge) LPCVD

- SIPOS (Semi-Insulating Polycrystalline Silicon)

- Polycrystalline Silicon Carbide

- Epitaxial Silicon

- Nano Materials LPCVD